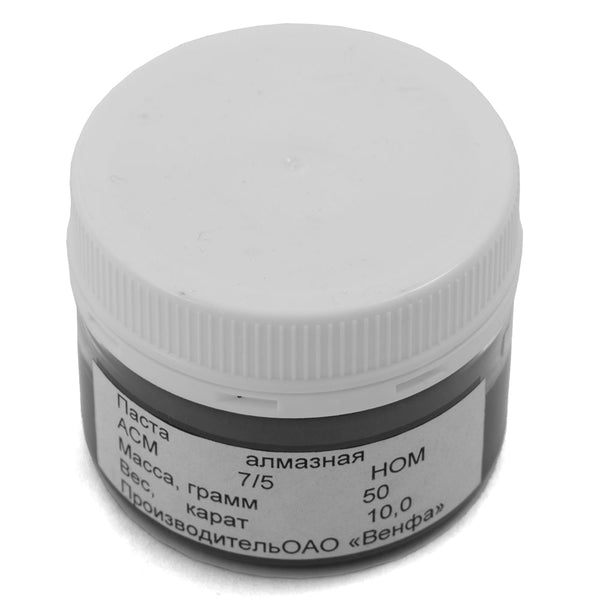

Venev Orion³ Series Resin CBN Series is the first CBN product developed by Venev Industrial Diamonds. Venev Orion³ ('Orion Cubed') is made in Edge Pro form-factor and is used for sharpening knives on Hapstone, TSProf, and all Edge Pro compatible guided sharpening systems. CBN (Cubic Boron Nitride) is the second-hardest material after diamond.

Venev Orion³ consists of a 3mm-thick CBN-bearing plate mounted on an Edge Pro aluminum base. The CBN-bearing plate contains evenly distributed CBN grains with resin bonding.

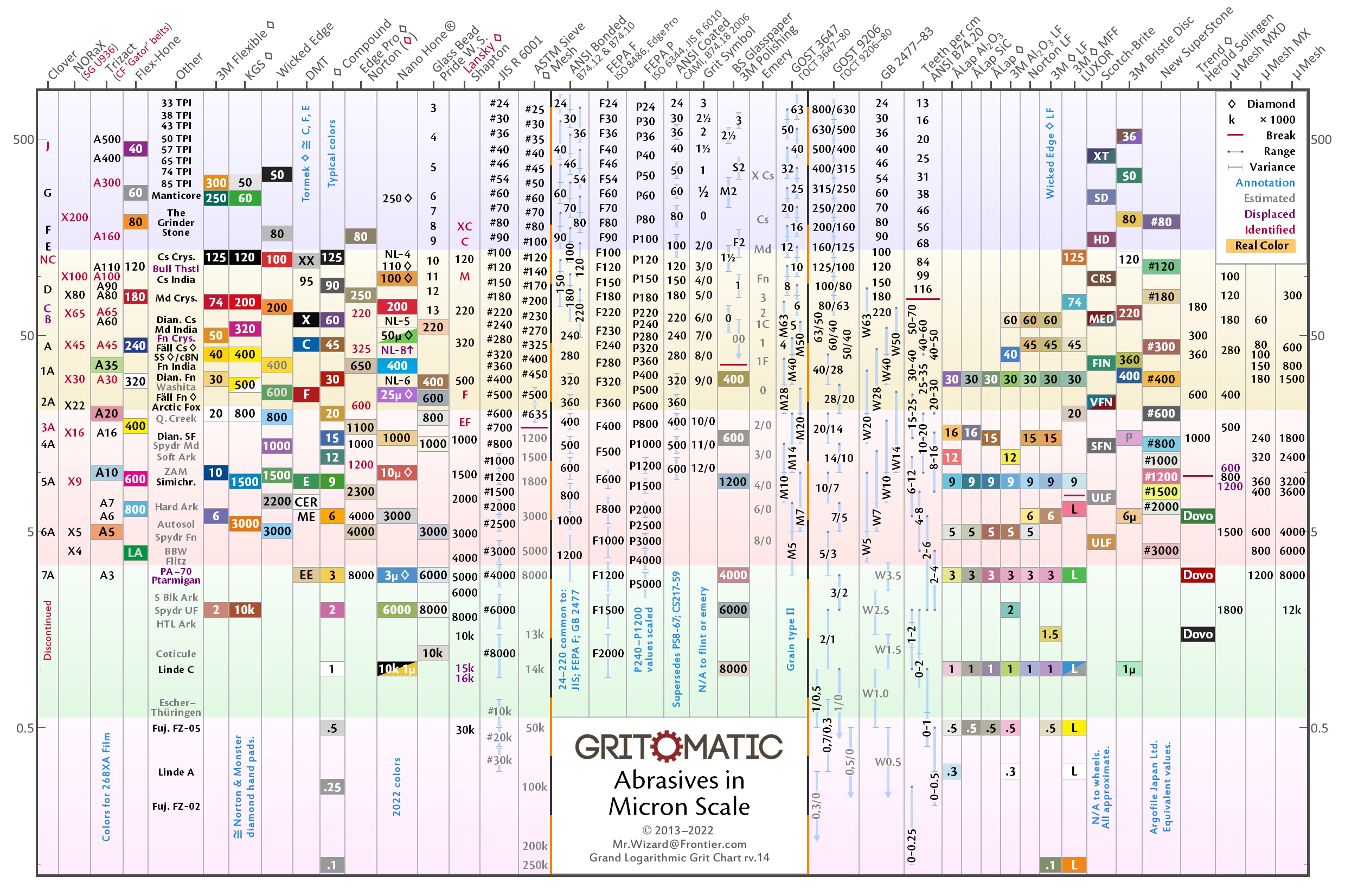

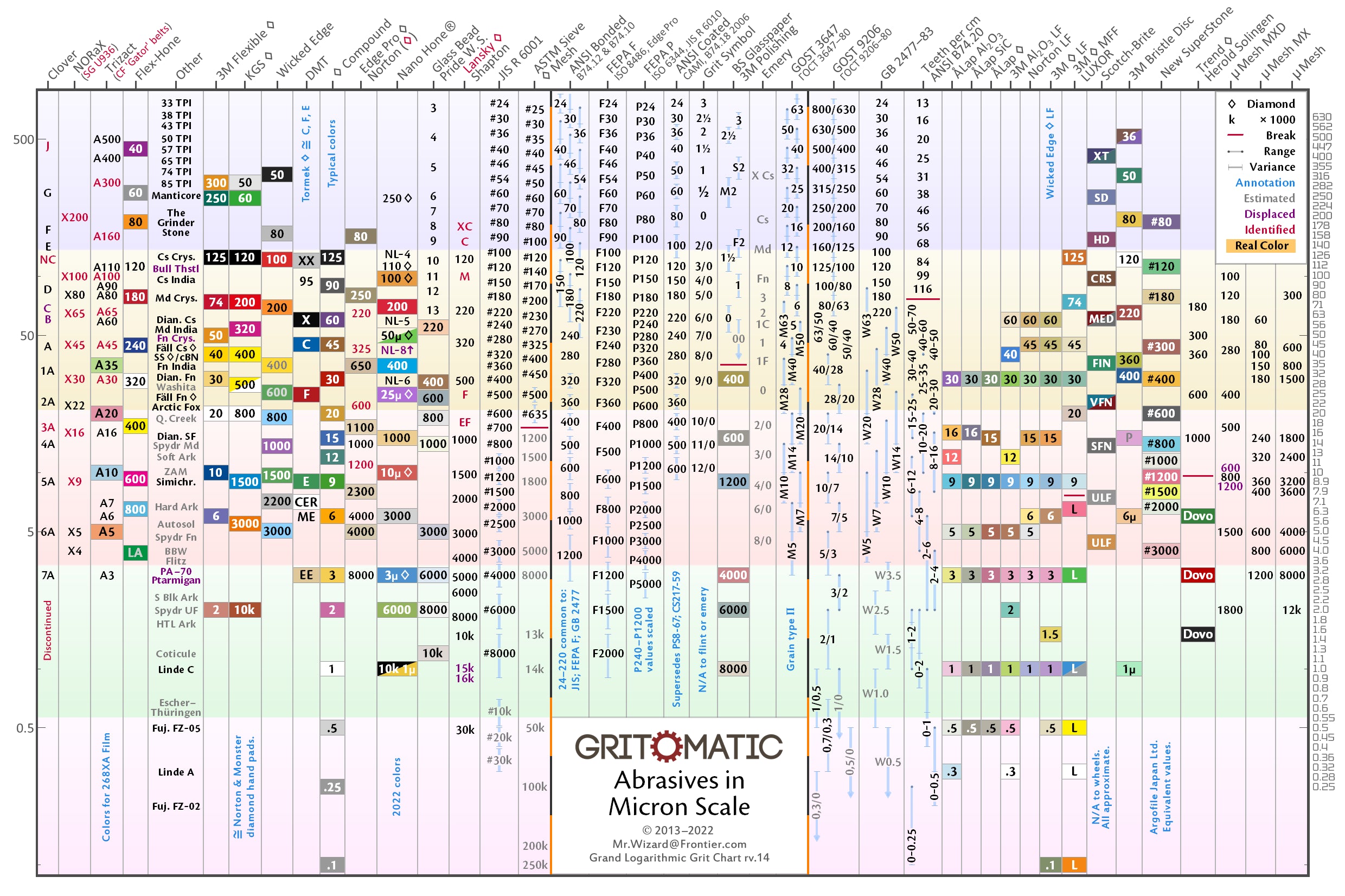

All Venev stones use FEPA-F grit classification. Orion³ series is available in 7 grits. F80 to F240 utilize wear-resistant legacy binder, F400 to F2000 utilize OSB binder with no abrasive particles in the composition.

How to use

Venev CBN stones are recommended to be used with water as a lubricant for the best feedback. The stones don't absorb water. Splash water on the stone's surface and keep it wet.

Metallic Binders (MMC)

M2-01 - Copper-tin bronze alloy.

MS-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with silicon carbide.

MB-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with boron carbide.

MS-1A - Metal-matrix composite (MMC) - Aluminum-copper alloy reinforced with silicon carbide.

Resin Binders

B1-10 - Boron-modified phenolic resin (BPF) composite - Made of powdered bakelite, copper additive

B2-01 - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, iron additive (softer than В1-10)

В2-01М - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, copper additive (softer than В2-01)

OSB (OCB) – A proprietary phenolic resin composite.

(OSB and OCB refer to the same binder; the difference arises from a transliteration quirk of the Cyrillic “ОСБ,” which can be rendered as either “OSB” or “OCB” in Latin script.)

| Code | Diamond Series | CBN Series | Dimensions | Bond | Class |

|---|---|---|---|---|---|

| CBR | Cerberus | 100×17×10×2×2 | Resin | Dual‑sided Premium | |

| UMI | Ursa | 150×16×10×1×1 | Resin | Dual‑sided Standard | |

| CEN | Centaur | Centaur³ | 150×25×10×1×1 | Resin | Dual‑sided Standard |

| MON | Unicorn🚀 | Unicorn³🚀 | 150×25×14×3×3 | Resin | Dual‑sided Premium |

| CMA | Greater Dog | 98×40×10×1×1 | Resin | Dual‑sided Standard | |

| PHE | Phoenix | 200×83×10×1×1 | Resin | Dual‑sided Standard | |

| DRA | Dragon | 200×83×12×2×2 | Resin | Dual‑sided Premium | |

| CHA | Chameleon🚀 | Chameleon³🚀 | 150×25×6×3×3 | Metallic | Dual‑sided Solid |

| SCO | Scorpion | 100×25×8×2 | Resin | Single‑sided Mounted | |

| ORI | Orion | Orion³ | 150×25×6×3 | Resin | Single‑sided Mounted |

| SGR | Archer 𝘎𝘦𝘯𝟤⌛ | Archer³ | 150×25×3 | Metallic | Single‑sided Variative |

| GEM | Gemini 𝘎𝘦𝘯𝟤🚀 | 150×12×3 R40 | Metallic | Single‑sided Mounted | |

| SCL | Sculptor⌛ | 150×12×3 | Metallic | Single‑sided Mounted |

Resin Dual Premium Resin Dual Standard Resin Single Mounted 🚀 Released ⌛ Soon

Dimensions notation.

Monolayer solid abrasives have 3 numbers: length × width × thickness.

Single-sided abrasives with backing have 4 numbers: length × width × full thickness × thickness of abrasive.

Dual-sided abrasives have 5 numbers: length × width × full thickness × thickness of abrasive #1 × thickness of abrasive #2 (both sides)

If thickness is variable, the minimum thickness is noted.

For curved abrasives, a radius of curvature inmm is added: R40.

![Venev Orion³ Series Resin CBN [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-orion-series-resin-cbn-for-edge-pro_490x.progressive.jpg?v=1755456155)

![Venev Orion³ Series Resin CBN [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_c06b947b-0f6e-4428-8ff0-42fea5cc7d39_490x.progressive.jpg?v=1755456155)

![Venev Orion³ Series Resin CBN [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-orion-series-resin-cbn-for-edge-pro_70x.progressive.jpg?v=1755456155)

![Venev Orion³ Series Resin CBN [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_c06b947b-0f6e-4428-8ff0-42fea5cc7d39_70x.progressive.jpg?v=1755456155)

![Venev Orion Series Diamond [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-bonded-diamond-for-edge-pro_600x.progressive.jpg?v=1755454863)

![Venev Gemini Series Curved Diamond [6" x ½"]](http://www.gritomatic.com/cdn/shop/files/curved-metallic-bonded-diamond-for-edge-pro_600x.progressive.jpg?v=1760270548)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28yellow_29_600x.progressive.jpg?v=1755455413)

![Venev Cerberus Dog Series Dual Side Diamond [4" x 0.6"]](http://www.gritomatic.com/cdn/shop/files/venev-cerberus-dog-series-dual-side-diamond_600x.progressive.jpg?v=1755452692)