Venev Phoenix Series Dual Side Diamond 8" x 3"

SKU: PHE-B100-80.150

AVAILABILITY: Out of Stock

Free Shipping

on orders over $50

Returns in 14 Days

following delivery date

Military Discounts

active, retired, veterans

Venev Phoenix Series Dual Side Diamonds are used for freehand sharpening knives. Diamond sharpening stones offer excellent performance in sharpening knives of any steel.

Phoenix Series is dual side diamonds with of two 1mm-thick diamond-bearing layers on the aluminum plate. The diamond-bearing layers contain evenly distributed diamond grains with resin bonding. The manufacture of bonded diamonds is more complex than for coated diamonds. Bonded diamonds give the sharpening stone a much longer lifespan.

The OCB version of Venev Diamonds utilizes a brand-new yellow binder with no abrasive particles in the composition. OCB is available in fine grits only and offers better scratch-free sharpening results.

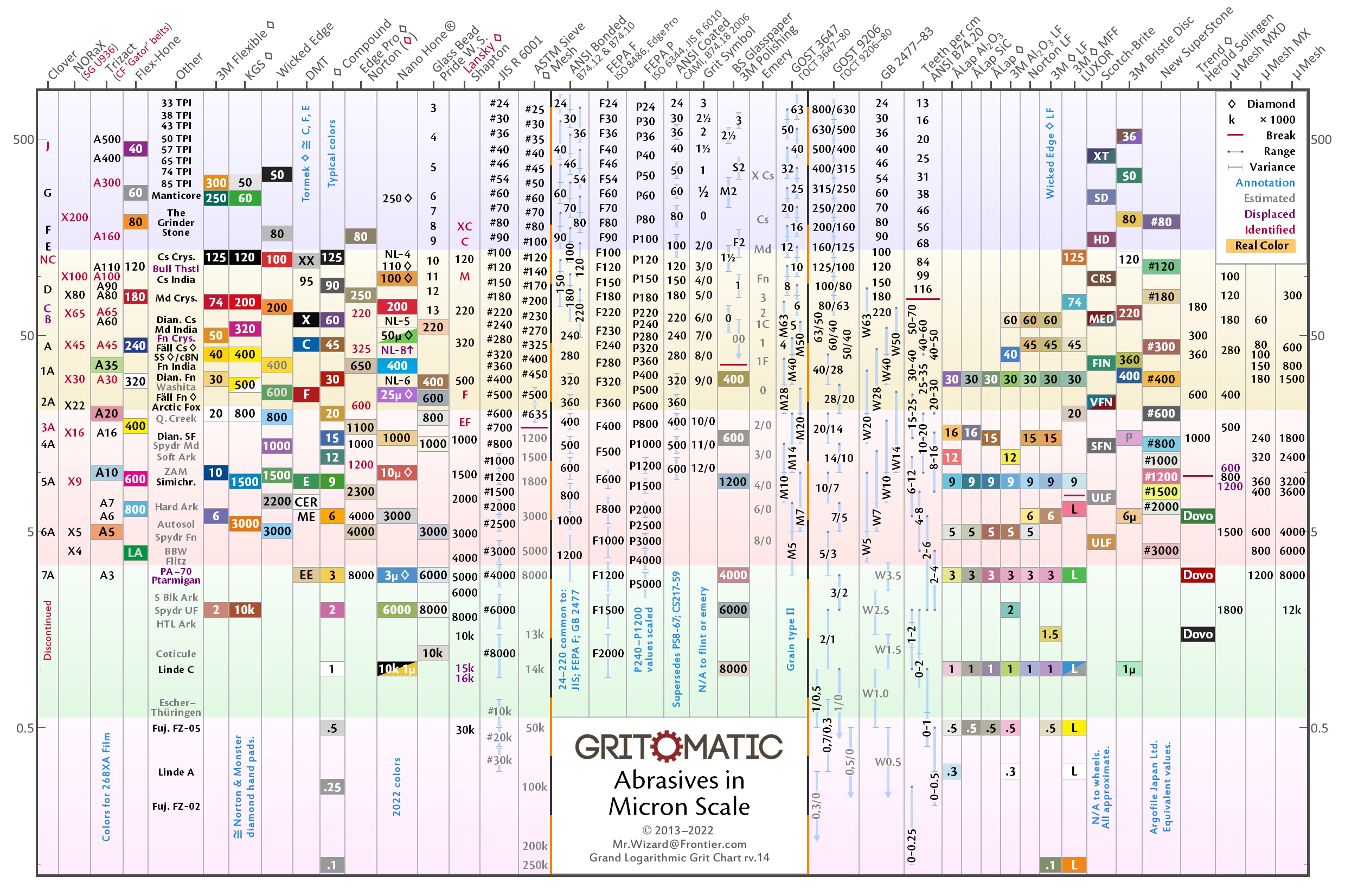

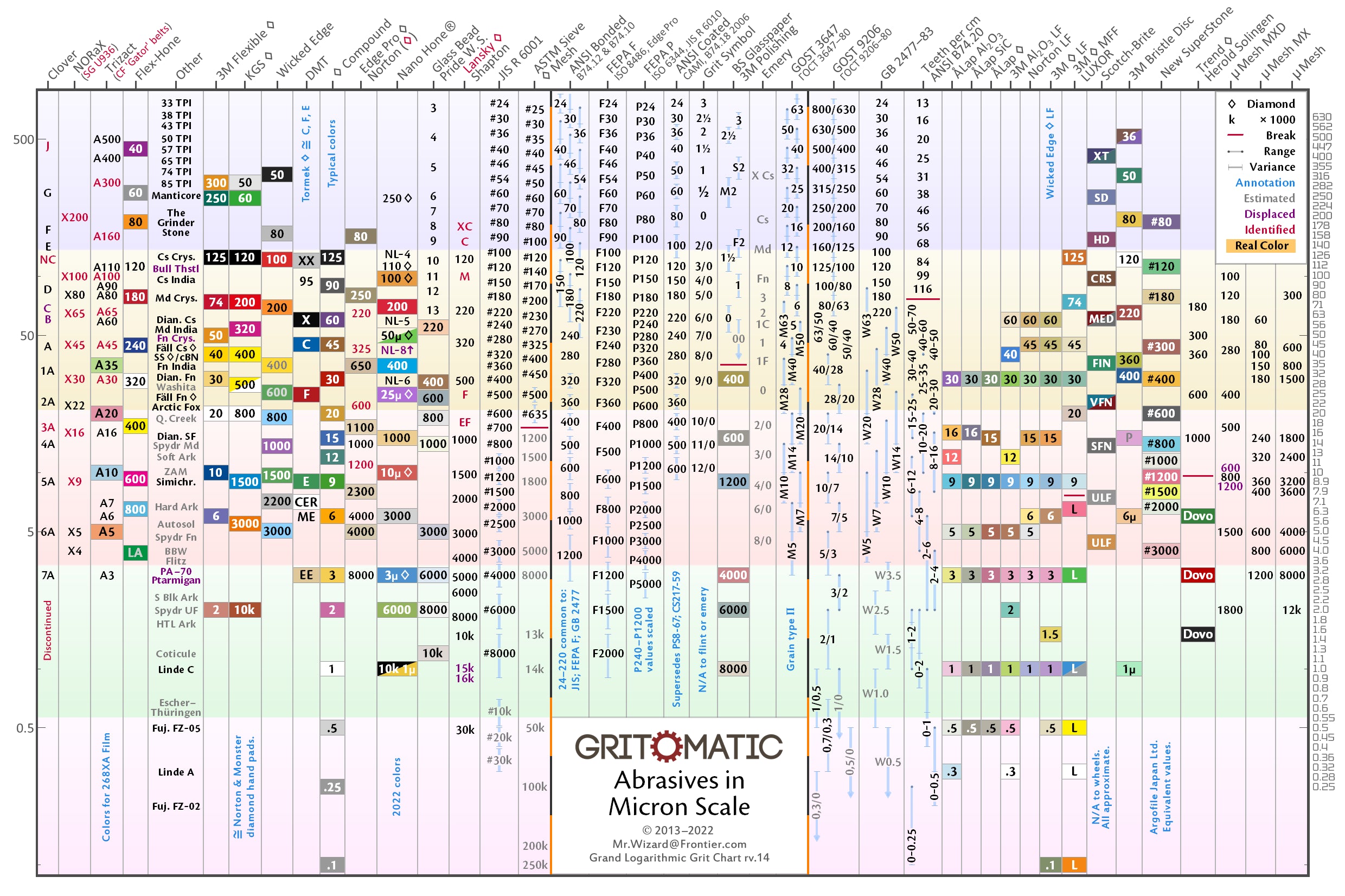

All Venev diamonds use FEPA-F grit classification. Phoenix Series is available in five grit combinations.

- F80 + F150

- F100 + F240

- F240 + F400 OCB

- F400 OCB + F800 OCB

- F800 OCB + F1200 OCB

F80 to F240 utilize legacy binder. F400 to F2000 utilize OCB binder. All combinations are available in 100% diamond concentration only.

Specification

- Product size: 200 x 83 x 10mm (8" x 3¼" x 3/8")

- Weight: 380 g (14 oz)

- Abrasive: Synthetic Diamonds with resin bonding

- Extra materials: Aluminum

- Flatness tolerance: up to 0.3mm

How to use

Venev Diamonds are recommended to be used with water as a lubricant for the best feedback. The diamond does not absorb water. Splash water on the stone's surface. Dry usage is an acceptable practice, although it results in faster wearing and speeds up stone loading.

Phoenix Series Diamonds may have the flatness tolerance up to 0.3mm.

| Code | Diamond Series | CBN Series | Dimensions | Bond | Class |

|---|---|---|---|---|---|

| CBR | Cerberus | 100×17×10×2×2 | Resin | Dual‑sided Premium | |

| UMI | Ursa | 150×16×10×1×1 | Resin | Dual‑sided Standard | |

| CEN | Centaur | Centaur³ | 150×25×10×1×1 | Resin | Dual‑sided Standard |

| MON | Unicorn🚀 | Unicorn³🚀 | 150×25×14×3×3 | Resin | Dual‑sided Premium |

| CMA | Greater Dog | 98×40×10×1×1 | Resin | Dual‑sided Standard | |

| PHE | Phoenix | 200×83×10×1×1 | Resin | Dual‑sided Standard | |

| DRA | Dragon | 200×83×12×2×2 | Resin | Dual‑sided Premium | |

| CHA | Chameleon🚀 | Chameleon³🚀 | 150×25×6×3×3 | Metallic | Dual‑sided Solid |

| SCO | Scorpion | 100×25×8×2 | Resin | Single‑sided Mounted | |

| ORI | Orion | Orion³ | 150×25×6×3 | Resin | Single‑sided Mounted |

| SGR | Archer 𝘎𝘦𝘯𝟤⌛ | Archer³ | 150×25×3 | Metallic | Single‑sided Variative |

| GEM | Gemini 𝘎𝘦𝘯𝟤🚀 | 150×12×3 R40 | Metallic | Single‑sided Mounted | |

| SCL | Sculptor🚀 | 150×12×3 | Metallic | Single‑sided Mounted |

Resin Dual Premium Resin Dual Standard Resin Single Mounted 🚀 Released ⌛ Soon

Dimensions notation.

Monolayer solid abrasives have 3 numbers: length × width × thickness.

Single-sided abrasives with backing have 4 numbers: length × width × full thickness × thickness of abrasive.

Dual-sided abrasives have 5 numbers: length × width × full thickness × thickness of abrasive #1 × thickness of abrasive #2 (both sides)

If thickness is variable, the minimum thickness is noted.

For curved abrasives, a radius of curvature inmm is added: R40.

Metallic Binders (MMC)

- M2-01 - Copper-tin bronze alloy.

- MS-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with silicon carbide.

- MB-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with boron carbide.

- MS-1A - Metal-matrix composite (MMC) - Aluminum-copper alloy reinforced with silicon carbide.

Resin Binders

- B1-10 - Boron-modified phenolic resin (BPF) composite - Made of powdered bakelite, copper additive

- B2-01 - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, iron additive (softer than В1-10)

- В2-01М - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, copper additive (softer than В2-01)

- OSB (OCB) – A proprietary phenolic resin composite.

(OSB and OCB refer to the same binder; the difference arises from a transliteration quirk of the Cyrillic “ОСБ,” which can be rendered as either “OSB” or “OCB” in Latin script.)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28yellow_29_490x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_490x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28brown_29_490x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28red_29_490x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28yellow_29_70x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_70x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28brown_29_70x.progressive.jpg?v=1764726846)

![Venev Phoenix Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-phoenix-series-diamond_28red_29_70x.progressive.jpg?v=1764726846)

![Venev Orion Series Diamond [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-bonded-diamond-for-edge-pro_600x.progressive.jpg?v=1764726752)

![Venev Centaur Series Dual Side Diamond [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond_600x.progressive.jpg?v=1764726757)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_600x.progressive.jpg?v=1764726778)

![Venev Dragon Series Dual Side Diamond [8" x 3"]](http://www.gritomatic.com/cdn/shop/files/8-x-3-venev-dragon-series-diamond_28yellow_29_600x.progressive.jpg?v=1764726840)