![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_490x.progressive.jpg?v=1739343460)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_fbe7c817-c5f1-4d6e-8608-c5bd97931305_490x.progressive.jpg?v=1739343460)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_70x.progressive.jpg?v=1739343460)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_fbe7c817-c5f1-4d6e-8608-c5bd97931305_70x.progressive.jpg?v=1739343460)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_490x.progressive.jpg?v=1739343460)

![Venev Centaur Series Dual Side Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-form-factors_fbe7c817-c5f1-4d6e-8608-c5bd97931305_490x.progressive.jpg?v=1739343460)

Venev Centaur Series Dual Side Diamond Stone Set 6" x 1"

- #1 Best Seller in #️⃣6" Stone Sets

SKU: SET-CEN-BETACENTAURI

AVAILABILITY: In stock (3 items)

Free Shipping

on orders over $50

Returns in 14 Days

following delivery date

US Customer Support

(470) 227-7960

Venev Centaur Series Dual Side Diamonds are used for sharpening knives on Hapstone and TSProf guided knife sharpeners, as well as freehand sharpening. Diamond sharpening stones offer excellent performance in sharpening knives of any steel.

Centaur Series is dual side diamond with two 1mm-thick diamond-bearing layers on the aluminum plate. The diamond-bearing plate contains evenly distributed diamond grains with resin bonding. The manufacture of bonded diamonds is more complex than for coated diamonds. Bonded diamonds provide better feedback and give the sharpening stone a much longer lifespan.

The OCB version of Venev Diamonds utilizes a brand-new yellow binder with no abrasive particles in the composition. OCB is available in fine grits only and offers better scratch-free sharpening results.

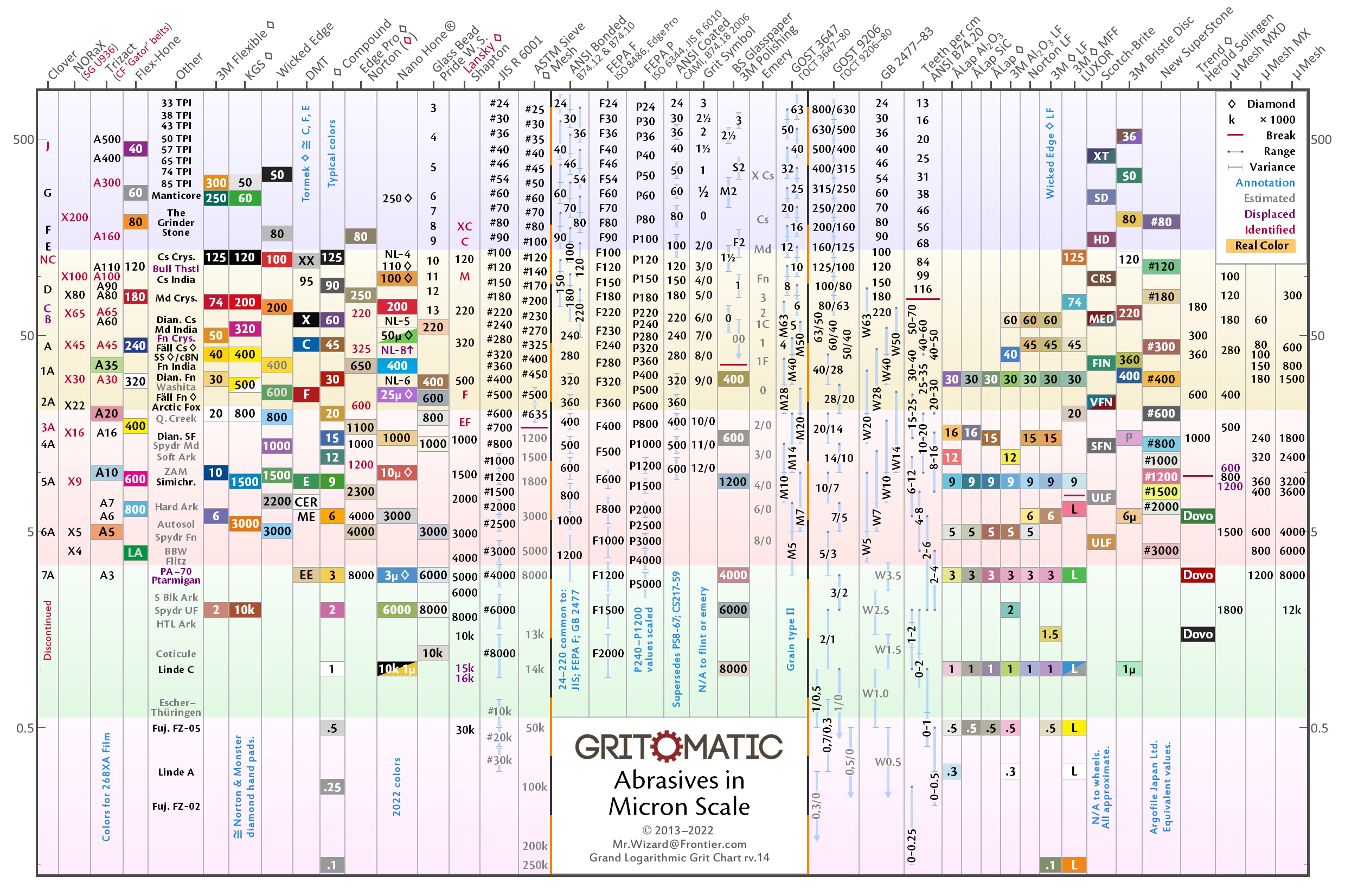

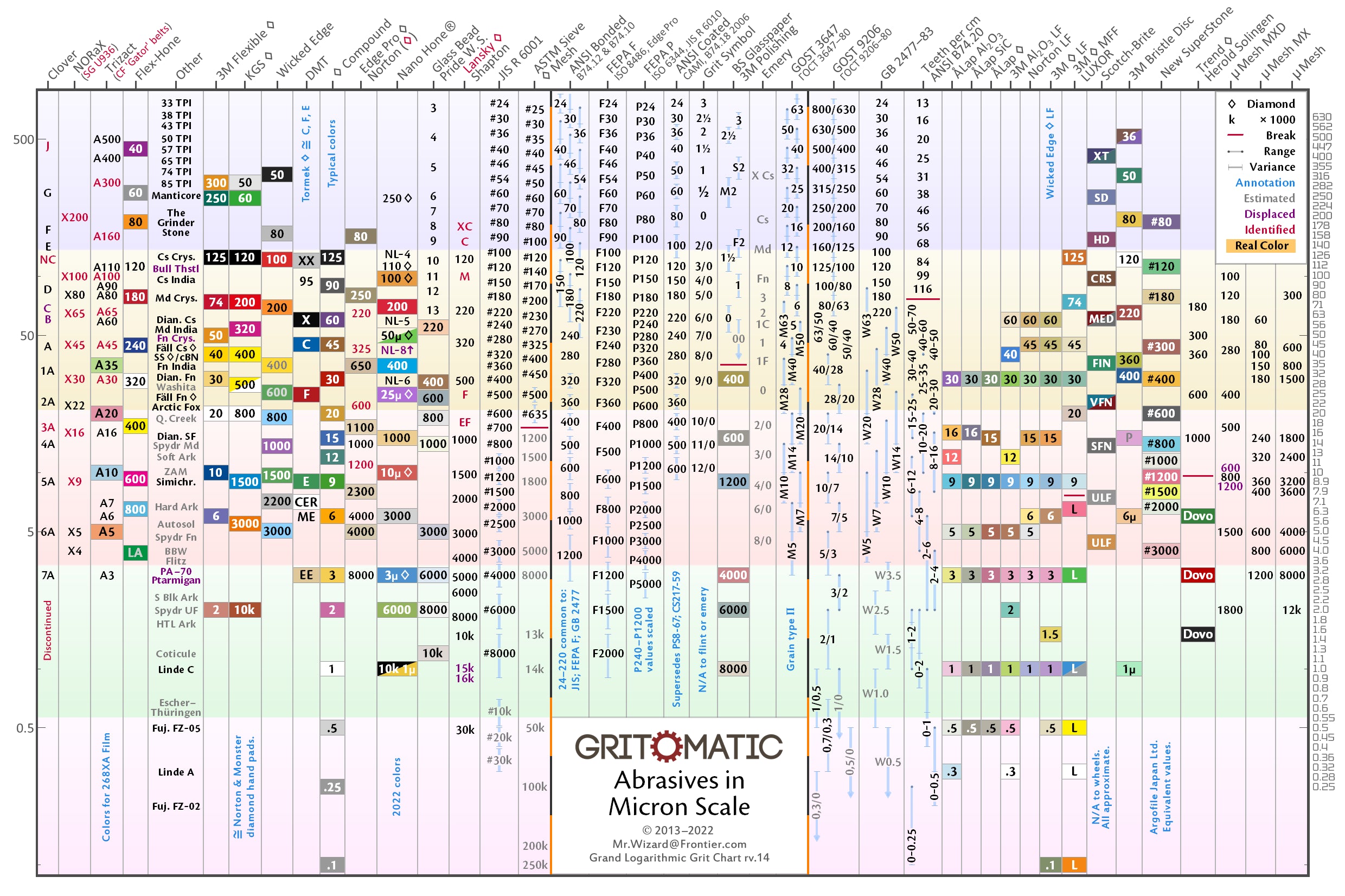

All Venev diamonds use FEPA-F grit classification. Centaur Series is available in six grit combinations.

- F80 + F150

- F100 + F240

- F240 + F400 OCB

- F400 OCB + F800 OCB

- F800 OCB + F1200 OCB

- F1200 OCB + F1500 OCB

F80 to F240 utilize legacy binder. F400 to F1200 utilize OCB binder.

Set composition

Stone set Beta Centauri:

- F80 + F150

- F240 + F400

- F800 + F1200

Specification

Each stone:

- Product size: 150 x 25 x 10mm (6" x 1" x 3/8")

- Weight: 90 g (3.2 oz)

- Abrasive: Synthetic Diamonds with phenol-formaldehyde bonding

- Extra materials: Aluminum

- Flatness tolerance: up to 0.2mm

How to use

Venev Diamonds are recommended to be used with water as a lubricant for the best feedback. The diamond does not absorb water. Splash water on the stone's surface. Dry usage is an acceptable practice, although it results in faster wearing and speeds up stone loading.

Venev Diamonds may have the flatness tolerance up to 0.2mm. Additional flattening and lapping can be performed by a customer to improve sharpening quality. We recommend using loose silicon carbide powder. Using a diamond lapping plate is not recommended.

SKU: SET-TSDIAM

AVAILABILITY: Out of Stock

PRODUCT TYPE: Sharpening Stone Set

VENDOR: TSProf

TSProf Diamond Plates provide fast metal removal and can be used for the repair of damaged cutting edges. Electroplated diamonds don't require preparation.The set consists of 5 diamonds: 150, 220, 400, 600, and 1000 grit. Diamonds are recommended to be...

SKU: SET-BORIDE-5-T2

AVAILABILITY: In stock (24 items)

PRODUCT TYPE: Sharpening Stone Set

VENDOR: Boride

Boride sharpening stones are used for sharpening knives on Edge Pro sharpeners. Boride offers a wide range of stones with different performance values and different rates of wear. Boride T2 series stones are made of aluminum oxide. All Boride stones...

SKU: SET-MATRIX

AVAILABILITY: In stock (20 items)

PRODUCT TYPE: Sharpening Stone Set

VENDOR: Edge Pro

Edge Pro Diamond Matrix Stones are used for sharpening knives on Edge Pro and Hapstone knife sharpeners. Diamond sharpening stones offer excellent performance in sharpening knives of any steel.The full set includes all 6 grits from 80 to 4000.Matrix Diamonds consist of a 1.6...

SKU: SET-ORI-SIRIUS

AVAILABILITY: In stock (13 items)

PRODUCT TYPE: Sharpening Stone Set

VENDOR: Venev Industrial Diamonds

Venev Bonded Diamonds are used for sharpening knives on Hapstone and Edge Pro knife sharpeners. Diamond sharpening stones offer excellent performance in sharpening knives of any steel.Venev Diamonds consist of a 3 mm-thick diamond-bearing plate on an Edge Pro aluminum...

![TSProf Diamond Plate Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/tsprof-diamond-set-for-edge-pro_600x.progressive.jpg?v=1739343482)

![Boride T2 Series Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/boride-t2-series-stone-set-for-edge-pro_600x.progressive.jpg?v=1739342297)

![Edge Pro Diamond Matrix Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/edge-pro-diamond-matrix-stone-set-for-edge-pro_600x.progressive.jpg?v=1739344617)

![Venev Orion Series Diamond Stone Set [6" x 1"]](http://www.gritomatic.com/cdn/shop/files/venev-orion-series-diamond-set-for-edge-pro_600x.progressive.jpg?v=1739346756)