FAQ: Why is my extra-coarse diamond slow?

Posted by KONSTANTIN MARTYNENKO

Why is my extra-coarse diamond slow? The question seems simple but it's quite complex.

Abrasive Cutting Performance

The performance of abrasive cutting depends on numerous factors. While many relationships can be explained, not all can. Sometimes, abrasive A has zero cutting performance on steel B, or causes blade chipping, extreme stone dishing, glazing, or balding. Often, these specific incompatibilities can't be explained and must simply be accepted.

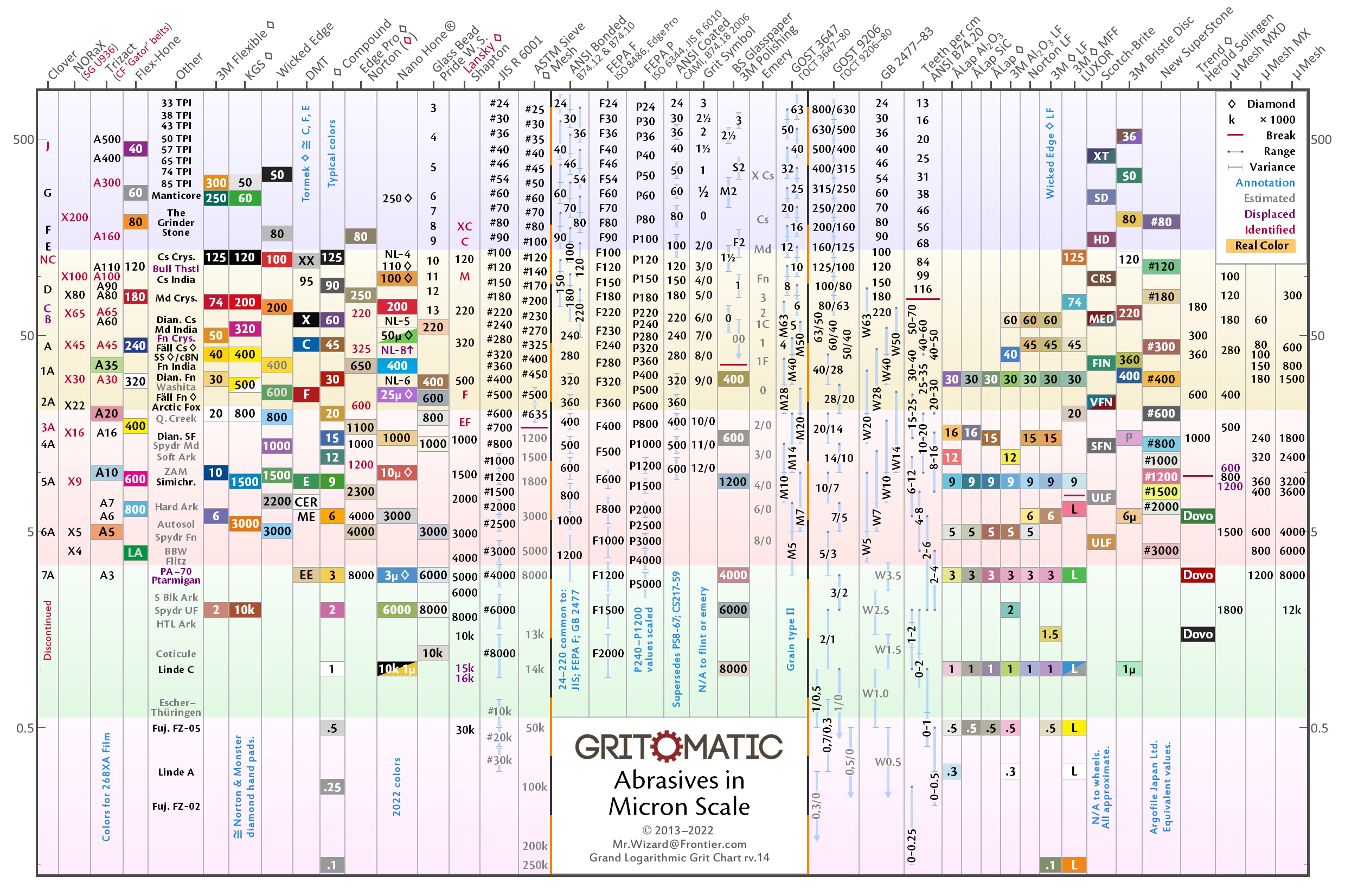

Grit Value and Cutting Performance

Grit value is a major factor affecting cutting performance. Intuitively, one might think "coarser" means "faster" because larger particles remove more metal. However, this isn't true for extra-coarse grits. Up to a certain point known as "the diminishing return," the opposite is true: "finer" means "faster." The optimal point is unique for each specific combination of abrasive, grit value, surface condition, break-in period, lubrication, steel type, heat treatment, scratch pattern, contact area, pressure, attack angle, and many other factors. This effect is present in all abrasives, not just diamonds. For power grinders like belt sanders, the optimal point is usually within the 24-60 grit range. In manual sharpening, where pressure is much lower, it’s typically within the 120-400 grit range.

Factors Influencing the Optimal Point

- Break-in Period: A new extra-coarse stone out-of-the-box has particles protruding at different heights, with only the tallest particles working. The break-in period makes particle height uniform, increasing the density of particles in contact.

- Steel Hardness: Soft steel allows protruding particles to penetrate deeper, enhancing the performance of extra-coarse stones.

- Pressure: When performance is low, applying more pressure can force protruding particles to penetrate deeper, temporarily increasing performance. However, this can lead to negative effects such as steel weakness, internal structural damage, abrasive grain rounding, fast stone loading, glazing, dishing, and balding.

- Blade Bevel Width: A narrow bevel has a small contact area, making the extra-coarse stone less effective.

- Blade Bevel Roughness: Extra-coarse stones may not work well on a mirror polish as particles will glide. They work much faster on a factory grind.

- Binder for Diamonds: Electroplated diamonds generally perform well in the extra-coarse grit range for most steels. For bonded diamonds, CBN, and traditional abrasives, performance is conditional.

Diamond Plate Before Break-in Period:

Diamond Plate After Break-in Period:

TAGS: